Robotics

Robotics

Developing the vision system for the 2016 robot ball launcher.

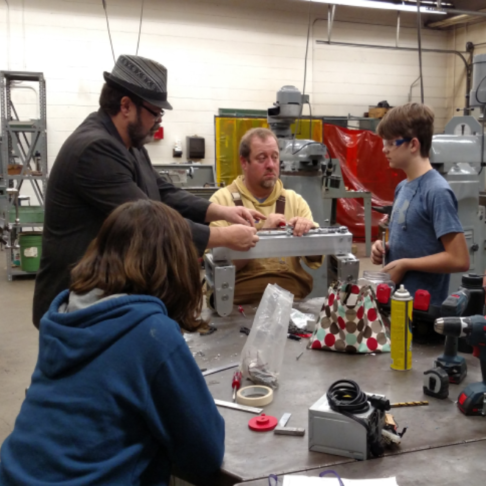

Designing the 2017 bot drivetrain with mentors.

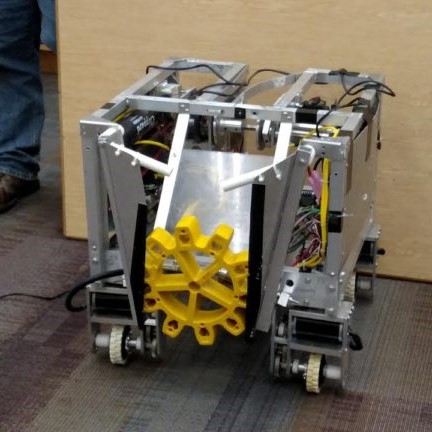

Our 2017 robot, The Gear Gobbler, in its completed state.

Climbing with another major team in 2018.

Celebrating the climb in the previous picture.

Our 2016 robot, including a climbing arm and ball launcher.

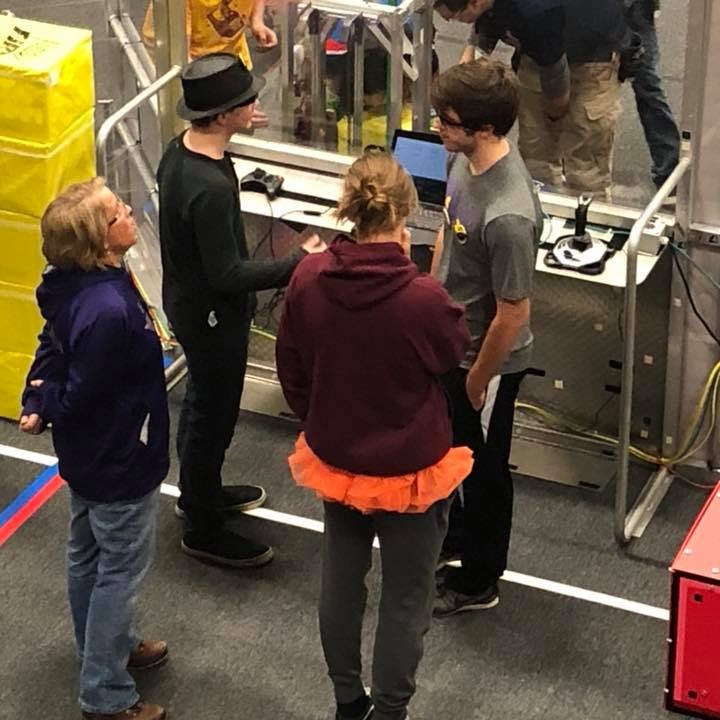

Discussing driving tactics in 2018 competitions.

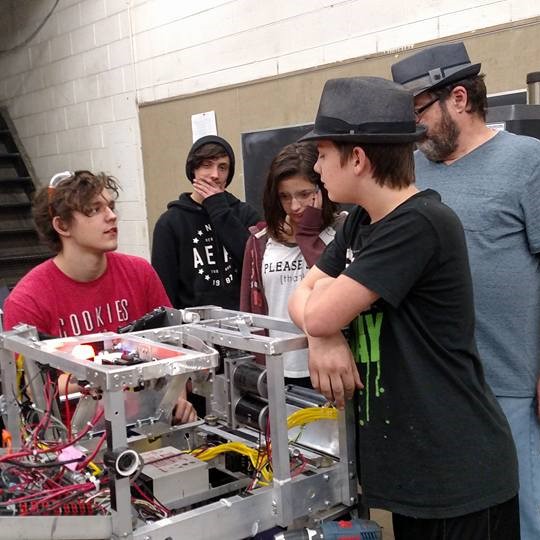

Working with the team to develop the best solutions.

The team mascot in my first year. Wearing the best hat, 2015.

Exhaustion from the second day at competitions, 2015.

FRC: Premise and Purpose

Six weeks. A manual of rules. Under 120 pounds.

First Robotics Competition (FRC) is a annual robotics competition for high school students and their mentors. Students are given six weeks to design, build, program, and test their bot before multiple competitions against other teams, where students will meet many like minded individuals.

The games are annouced in Janurary, and rule manuals documenting the field layout, game premise, etc will be released to the public. Bots must be 120 pounds or lighter and must pass a plethora of saftey and game rules. It is then a race to make a practical machine, with all challenges from FRC incorporating real life challenges.

I cannot wait to return to FRC, and plan to offer a mentorship to Team 5641 in a few years after developing my software skills further.

Team 5641: Four Years of Robotics

2015 - FRC: Recycle Rush

My first year of robotics. My contribution to this year was minimal, only acting as a builder and team mascot due to my age, still in seventh grade. The robot was a tall automation that used copper pipes as linear bearing guides. When the driver pulled up to the tote loading station, an operator could feed up to five totes to the robot for automatic stacking. After being stacked, the stack is placed in its designated location for points.

--- For a video of this bot running, please click here. ---

2016 - FRC: Stronghold

After the previous year, many exceptions were made to let me contribute to the team. At this point, I was contributing to building and machining of most bot components due to owning multiple relevant, large CNC machines. This was our primary driver and programmers last year, so much of my time was spent learning from him.

The bot was capable of shooting balls into a tower from camera feedback to the driver station. You can see me developing the code for the launcher in picture #1.

2017 - FRC: Steamworks

Following the graduation of our primary programmer, writing code fell into my hands. Using C++, I learned how to read camera and ultrasonic data to develop autonomous statements.

The challenge had many parts, including manipulating plastic gears, balls and climbing at the end of round. The team decided to master one issue instead of all three, leading to a fast and efficent gear handler.

This bot can be seen in picture #3 and #8.

2018 - FRC: Power Up

Driver, programmer, builder. My final year with Team 5641. To adapt in my new role, the software was changed to C# after getting Visual Studio to compile to roboRio controllers. This allowed me to write more, faster, and still practice my driving. This bot had the ability to lift milk crates up to six feet, additionaly, climb during the end phase. Autonomous statements allowed us to place a cube without driver control.

--- For a video of this bot running, please click here. ---

Custom Manufacturing

Custom Manufacturing

AL - The Bridgeport Series 1 CNC Mill.

Betty - The Brown & Sharpe 618 Micromaster.

The Grizzly G9972Z Lathe w/ DRO.

The Handmade Wood Planer During Construction.

Frohring Mini-Jector - Under Revitalization.

Fellows No. 7 - Under Revitalization.

My journey with CNC machining began with my most prized possesion, the CNC mill. Named AL, a Bridgeport Series 1 CNC mill restored to run Mach 3 on Windows XP. We have a habit of buying and restoring machines from manufacturing auctions. Among the list of machines we've purchased is an injection moulder, a gear shaper and hobber, a manual lathe, and a CNC surface grinder. We have also made many advancements with 3d printing, owning four printers, three filament and one resin.

Al was purchased when I was just seven years old. Manually scrubbing rust off with wire brushes on drills and repainting are always the first steps, before extensive rewiring and programming to restore the machine to modern CNC standards.

We use these machines to build robotics parts and most of all, other machines. We have manufactured a commercial scale wood planer, router table, and a crown moulding machine. The most recent use of these machines has been for prototyping robotics frames, but will soon make a belt sander.

The Machines Themselves

The Mill

Status: Fully Functional

Our Bridgeport Series 1 CNC mill fully restored, running Mach 3. Purchased in 2010 and finished the same year, the mill has been essential for building many other machines. This machine has manufactured robotics parts, machine parts, and many more. The computer needs replaced with a Raspberry Pi with LinuxCNC, along with new H-Bridge motor drivers.

The Lathe

Status: Fully Functional

Our Grizzly G9972Z lathe was purchased in 2009 before AL. Modified to have a DRO, this Lathe has been used for many tasks. Axle creation, precision linear bearing creation, boring, and hobing of hex holes to name a few. This machine has proven quintessential for making precision equipment, and soon will be used to make my wedding ring.

The Surface Grinder

Status: Fully Functional

Our Brown & Sharpe 618 Micromaster, named Betty, was fully restored in 2013-2014. This machine is fully automatic, but does so with manual hydralic systems. It is capable of grinding metal surfaces to extreme tolerances, which can be measured on our precision granite surface table. This functionality is needed for making other machines.

The Gear Shaper

Status: Under Revitalization

Our Fellows No. 7 Gear Shaper purchased in 2020 has not been fully revitalized. It requires a new motor wired to the shops system, and some internal mechanisms to ensure the oil pump still operates. It is assumed to otherwise be functional, and is expected to be finished by the end of 2024 to early 2025.

The Injection Moulder

Status: Under Revitalization

Our Frohring Mini-Jector is also under repair. Purchased in 2020, it appears most machine functions are operational. The hydralic system leaks, and the extruder requires a plastic loader installed. Otherwise, electronics for extruder heat and hydralic control have been completed.

Crown Moulding Machine

Status: Fully Functional

The crown moulding machine was the first machine built using the shop. It can cut rough wood into crown moulding shapes, and is used actively for the construction of a second house owned by Elysium Innovations.

The Wood Planer

Status: Fully Functional

The wood planer was the second machine built in the shop. Capable of planing an 1/8th inch of rough cut oak wood in one pass, this machine is not to be trifled with. It provides perfectly smooth and sized boards from rough cut lumber. This lumber will then be used in cabinetry, hardwood flooring, and more.

Decommissioned

- Chemical Circuit Board Etcher

- Circuit Board CNC Drill

- Custom Arc Welder

Software Development

Software Development

Software Development is an important past-time of mine. My first project was an eBay inventory system for a side-hustle my mother was running.

This system included a web interface backed by C#, with data stored in MySql.

Craving a further understanding of software engineering, I asked my father for help hoping he would

teach me a language he frequently used, C++. He instead made me learn binary, its conversion into machine language and ASCII text. He claimed the fundamentals were far more important, and he was right.

Building from there, I designed stepper motor drivers

using PIC microcontrollers and C programming language.

Finally reaching my goal, I competed in First Robotics (FRC) for 2 years as a lead programmer, driver and engineer.

Developing autonomus statements based on sensor data including LiDAR, camera and precise CAN motor driver control feedback under the C++ language.

Since then, my hobby projects have

included a vast discord bot written in C#, composed of 4600 lines. Its abilities included voice streaming from most music platforms, database storage of server-specific data, and an integrated economy

with casino system. This bot is currently being rebuilt in C and will be publically released afterwards.

Finally, web development, which had to be learned from scratch to develop this website. It is my first, and I hope to continue honing my skills on all levels of the programming roadmap.

Skills

C#80%

C50%

C++50%

Assembly40%

APIs70%

SQL50%

HTML5 & CSS380%

JavaScript60%

Music Production

Music Production

Since a very young age, I've always had a passion to understand how the world around me works. Listening to music is no exception, digesting every sound in a production and trying to understand how that music was created is a never ending pursuit. Starting at 12 making mixes of other songs, and eventually using the same software to make my own music. After obtaining a Casio MIDI piano and practicing music theory, I was able to develop some simple chord progressions with melodies I enjoyed. My music frequently starts with a piano baseline and builds atmospheres around it. I am no music prodigy, but I enjoy manipulating soundwaves nonetheless.

Below is two great outlets to access my music. The s.t.i.l project is ongoing, so more songs will appear here over time. Songs can be found in all stores and music sharing platforms, including social media platforms. My music is independently licensed, released, and managed by myself on my own dime out of passion. Any comments or advice on how I can improve my sound is greatly appreciated.